The apparel and footwear industry faces huge challenges and for its survival, it must transform into a textiles economy that is based on circular systems.

The circular economy is restorative and regenerative by design and provides benefits for business, society, and the environment. The textile industry must therefore use resources wisely, maximize their potential, and minimize waste. A report by the Ellen McArthur Foundation provides a sustainable blueprint for the apparel industry that if implemented will result in a circular textiles economy.

The issue

“A New Textiles Economy: Redesigning Fashion’s Future” authored by the Ellen MacArthur Foundation, states that clothing production has doubled in the past 15 years and yet clothing utilization (the average number of times a garment is worn before it ceases to be used) has decreased by 36%.

Every second, a truckload of garments is thrown into a landfill, which means that less than 1% of material used to produce clothing is recycled into new clothing.

Non-renewable resources, such as oil to make polyester, fertilizers to grow cotton and chemicals to manufacture products are over sourced. Pollution, in the form of greenhouse gases and water contaminated with hazardous chemicals from textile processing is putting the planet at risk.

The textile industry is therefore in turmoil and must act fast.

The opportunity- creating a textiles economy

The report highlights opportunities that can drive transformative change in the apparel and footwear industry that will result in a new textiles economy. The recommendations are a series of new business models and behaviors based on the circular economy and cradle to cradle.

In a textiles economy, textiles are kept at their highest value during use, and then re-enter the economy after use, thereby never ending up as waste.

The philosophy embraces the circular economy and provides different areas within the supply chain where new circular business models can be developed and implemented.

The most important take away is that the entire industry needs to value its resources. A make-use-reuse circular approach must replace a take-make-use-dispose linear approach.

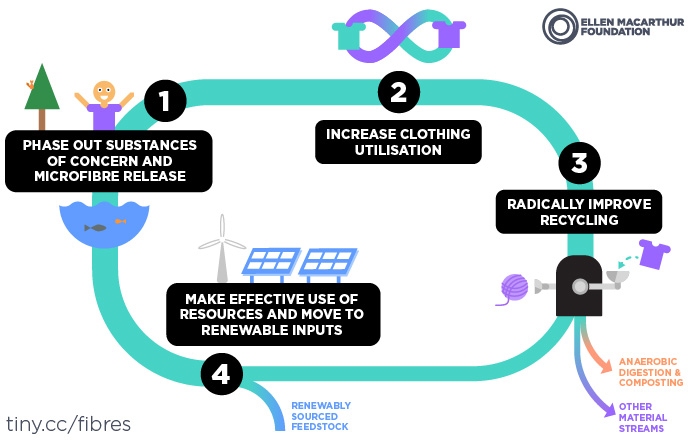

The following diagram, obtained from the report, is a blueprint for change.

Four areas of focus can be addressed in a textiles economy.

Circular textiles

Phase out substances of concern and fibre release

In a textiles economy, materials need to be safe and healthy so that they can be used again and again without any negative impact. There are two opportunities in this step:

- Phase out of substances of concern that are currently used in fibre, apparel and footwear manufacturing and replace with safer alternatives.

- Design materials and products using inherently safer chemistry by stimulating green chemistry research and new fibre innovation.

The fibre release refers specifically to microfibers that are shed from mostly synthetic apparel products, during wash and wear. The amount of plastic in the ocean is mind-boggling and the apparel industry is certainly a culprit.

Increase clothing utilization

I interpret this step as creating new business models that address apparel and footwear rather than chemicals and fibres.

Clothing utilization must increase. High quality clothing and access to clothes via new business models would help people shift their thinking to clothes as durable products instead of disposable items.

In a textiles economy, clothes are designed, sold, used and then reused by investing in the following opportunities:

- Scale rental schemes

- Make durability more attractive

- Increase clothing utilization

Radically improve recycling rates

I interpret this step to include fibre recycling as well as apparel recycling. The three broad areas are to

- Transform clothing design, apparel collection and reprocessing. (Design for disassembly)

- Pursue innovation to improve economics and recycling quality

- Stimulate demand for recycling materials

Use resources wisely and move to renewable resources

I interpret this step as being applicable to product (fibre and apparel) manufacturing and moving towards renewable resources. For example

- Use chemistry, tools, techniques and machinery that use less water and energy during product manufacture

- Obtain chemicals and fibres from renewable resources. Chemicals from food waste, plant oils or algae. Fibres from mushrooms, pineapple and spider DNA.

Impacts to your business?

Questions to consider:

- Did you design products to last a long time?

- How do you make purchasing decisions?

For help with sustainability, circularity and chemicals, contact Amanda Cattermole at (415) 412 8406 or Amanda@cattermoleconsulting.com. We can help you develop powerful solutions to protect your company and brand reputation.

Tips and Insights contains information to help you make informed sustainability decisions. Each post highlights a particular topic and includes questions you may want to consider for your business.