Today only a small number of chemicals used by American workers are regulated in the workplace. Many others are suspected of being harmful.

The U.S. Department of Labor’s Occupational Safety and Health Administration OSHA has developed a toolkit to help companies and businesses reduce hazardous chemicals in the workplace.

Transitioning to safer alternatives can be challenging, but OSHA has provided some guiding principles and a toolkit to help companies and employers make informed decisions about the chemicals used in their products and supply chains.

The toolkit helps businesses improve worker well-being through eliminating or reducing hazardous chemicals, while creating other benefits as well.

Benefits of using safer chemicals.

- A less hazardous workplace

- Cost Savings — By reducing expenses and future risks.

- Efficiency — By improving performance.

- Industry Leadership — By investing in innovation to stay competitive.

- Corporate Stewardship — By helping to advance socially responsible practices.

The toolkit is geared towards all types of businesses. It can help manufacturers that use chemicals in their production processes, or businesses that use products containing chemicals in their everyday operations.

The goal is for workers to get a better understanding of chemical use in their workplace, find opportunities for using safer chemicals, and engage with their employers throughout the process of identifying, evaluating, and transitioning to safer alternatives.

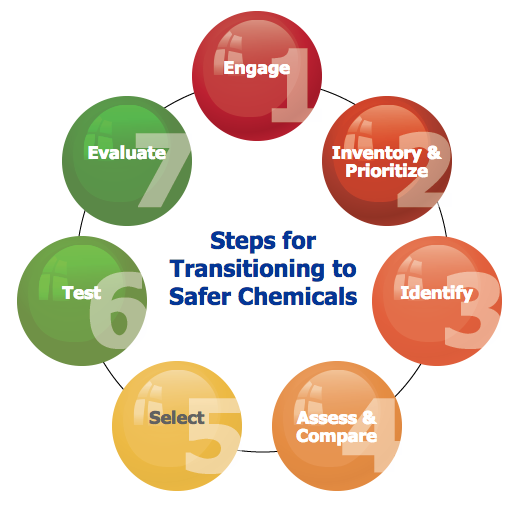

OSHA’s seven steps for transitioning to safer chemicals.

1. Form a team to develop a plan.

2. Examine the current chemical use. This will help prioritize chemicals that need to be phased out of the supply chain.

3. Identify safer alternatives to get a clear overview of your options.

4. Assess and compare alternatives by looking at hazards, cost and performance or conduct an Alternatives Assessment.

5. Select a safer alternative based on the hazard, performance and cost evaluations, or the result of the alternatives assessment.

6. Pilot the alternative to gain valuable information to help make informed decisions.

7. Implement the alternative and evaluate at full scale to monitor impacts and improve on the process.

Impact to your business

Questions to Consider:

- Do you have a system or approach to finding safer chemicals?

- Are you prioritizing which chemicals need to be replaced with safer alternatives?

For help with any issue associated with chemicals, contact Amanda Cattermole at (415) 412 8406 or Amanda@cattermoleconsulting.com. We can help you develop powerful solutions to protect your company and brand reputation that result in safer products manufactured in cleaner supply chains.

Tips and Insights contains information to help you make informed chemicals management decisions. Each post highlights a particular topic and includes questions for you to consider .